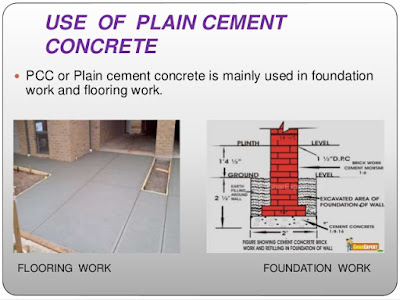

P.C.C means plain cement concrete and its also recognized as pre-cast concrete, cement concrete (CC), binding concrete etc. It is formed by blending the cement, aggregate(coarse or fine ),sand and water in proper ratios. PCC is strong in compression but poor in the tension and shear. It's mostly found in foundation work and flooring in building.

Applicable tools for forming PCC:

Generally, the following tools are utilized for developing Plain Cement Concrete.

• Wooden or Steel rammer

• Mixture machine (if any)

Density of PCC:

The density of PCC usually remains at 50mm over Brick Flat Soling (BFS). If BFS is not applied underneath PCC then the thickness should remain at 75¬mm. If the PCC is applied in car park area then the thickness should remain at 75mm over BFS.

Ratios of materials for PCC:

By volume, the ratio of cement, sand and brick chips in foundation or basement is 1:3:6. But, in car park area, the ratio changes to 1:2:4.

Placing and Compaction of PCC:

After PCC is placed for 24 hours, wet the concrete surface by drenching with water or by wrapping with moist gunny bags minimum 7 days.

Examining and Inspection:

• Verify the dimensions of form work of PCC prior to mixing concrete.

• Examine whether polythene sheet is placed over PCC bed.

• Verify the concrete slump (highest slump should have been 75mm)

• Ensure the thickness level of PCC prior to casting by providing steel pegs in concreting area or level pillar of fresh concrete at proper spaces.

• Verify the finish level of PCC by thread fixing with nails in form work.

• Make sure that the concrete is placing smoothly.

Applicable tools for forming PCC:

Generally, the following tools are utilized for developing Plain Cement Concrete.

• Wooden or Steel rammer

• Mixture machine (if any)

Density of PCC:

The density of PCC usually remains at 50mm over Brick Flat Soling (BFS). If BFS is not applied underneath PCC then the thickness should remain at 75¬mm. If the PCC is applied in car park area then the thickness should remain at 75mm over BFS.

Ratios of materials for PCC:

By volume, the ratio of cement, sand and brick chips in foundation or basement is 1:3:6. But, in car park area, the ratio changes to 1:2:4.

Placing and Compaction of PCC:

• Ensure brick soling/sand bed level for PCC is perfect.

• Develop form work for PCC with wooden plank according to stipulated dimensions.

• Cleanse dust or foreign or loose earth from concreting area.

• Wrap the bed of PCC with polythene.

• Produce level pillars of fresh concrete in the area at proper gapping but not in excess of 2m c/c both ways.

• Set the concrete smoothly (don’t through) from one side. Apply the mixed concrete within 45 minutes as soon as the water is mixed.

• The compaction and finishing of PCC should be done with wooden rammer.

• Create the surface of PCC coarsen for joining future work prior to concrete gets solidified.

Curing of PCC:

• Develop form work for PCC with wooden plank according to stipulated dimensions.

• Cleanse dust or foreign or loose earth from concreting area.

• Wrap the bed of PCC with polythene.

• Produce level pillars of fresh concrete in the area at proper gapping but not in excess of 2m c/c both ways.

• Set the concrete smoothly (don’t through) from one side. Apply the mixed concrete within 45 minutes as soon as the water is mixed.

• The compaction and finishing of PCC should be done with wooden rammer.

• Create the surface of PCC coarsen for joining future work prior to concrete gets solidified.

Curing of PCC:

After PCC is placed for 24 hours, wet the concrete surface by drenching with water or by wrapping with moist gunny bags minimum 7 days.

Examining and Inspection:

• Verify the dimensions of form work of PCC prior to mixing concrete.

• Examine whether polythene sheet is placed over PCC bed.

• Verify the concrete slump (highest slump should have been 75mm)

• Ensure the thickness level of PCC prior to casting by providing steel pegs in concreting area or level pillar of fresh concrete at proper spaces.

• Verify the finish level of PCC by thread fixing with nails in form work.

• Make sure that the concrete is placing smoothly.

Article Source : http://www.acivilengineer.com

No comments:

Post a Comment